Home / Newsletter / 91. Zaward’s Liquid Cooling Solutions for Energy Storage

91. Zaward’s Liquid Cooling Solutions for Energy Storage

Efficient storage systems not only enhance renewable energy use but also stabilize grids, ensuring consistent power supply, even in distant communities.

JAN 23, 2024

In today’s dynamic energy sector, the rise of renewable sources highlights the important role of reliable energy storage. Efficient storage systems enhance renewable energy use and stabilise grids, ensuring consistent power supply, even in distant communities.

Responding to market needs, ZAWARD, with over 27 years of expertise in cooling solutions, is dedicated to assisting our clients to achieve the best use of renewable energy. We are delighted to introduce our liquid cooling solutions tailored for energy storage applications.

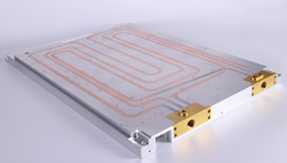

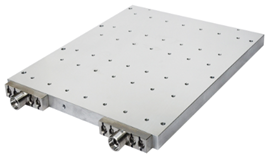

At Zaward, our liquid cooling solutions include buried pipe, friction stir welding (FSW), brazing, and composite welding processes, offering enhanced cooling efficiency to meet the rigorous demands of the new energy sector.

Product Pictures

Buried Cold Plate Buried Cold Plate

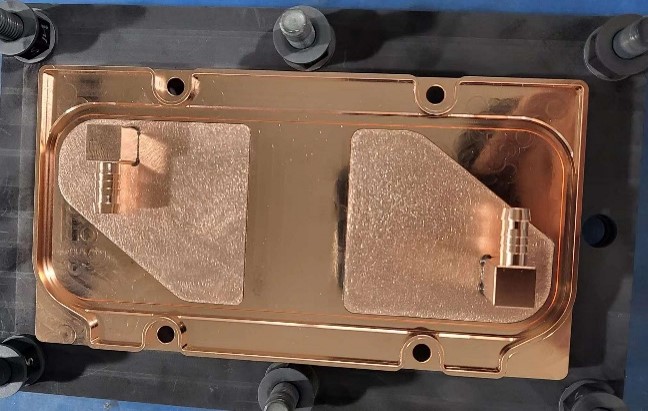

FSW Cold Plate Tunnel Brazed Cold Plate

Zaward’s Brazing & Welding Capabilities Include:

1.Friction Stir Welding (F.S.W) is a solid-state joining technique that joins two parts without melting the work piece material. It uses friction to stir and mix the parts together, creating a robust bond without needing any additional materials.

👓 Watch Friction Stir Welding process

2. Tunnel Brazing uses lower-melting solder to seamlessly join materials. This method minimizes deformation, providing smooth joints suitable for welding precision, complex, and components composed of different materials.

3. Vacuum Brazing joins components by heating a lower-melting filler material between them in a vacuum furnace. The vacuum environment ensures a clean, high-quality bond with reduced oxidation during the brazing process.

4. Flame Welding heating metals to their melting point using a flame heat source for joining.

5. High-Frequency Welding is a method that employs high-frequency current to generate resistance heat at the workpiece’s contact surface, creating a bond between the metal pieces under pressure or without it.

Supported by our dedicated team, we’re confident in our ability to customize our liquid cooling solutions to meet your energy storage applications.

🔎 Also read : Efficient Thermal Management for Energy Storage

Zaward is ready to assist you with any inquiries you may have and provide the most suitable solutions to meet your specific requirements. Welcome you to discuss your specific requirements and developments with us anytime.

For additional information or inquiries, please don’t hesitate to reach out to us and visit our website.