Having an issue with wide area of heat source but restricted by limitation of tooling machine to produce

size-appropriated heat sink? And conventional welding method decreases efficiency due to filler material and consumes higher energy as well as releases fume and smoke. In this case, “Friction Stir Welding” (FSW), a

solid-state joining process that joins two materials with pin tool, is the state of the art solution and popularly used in thermal and across other industry.

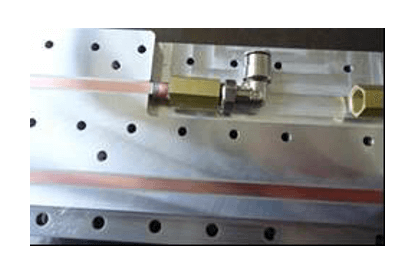

Placing pin tool between the joint area of two pieces of materials, the rotating shoulder creates friction heat which softens edges of the materials to a plastic state (but not melt). As the pin tool moves along, it generates welding pressure itself and stirs the two pieces together. Once the tool pulls away, the two pieces are joined into one solid-state bond and made in solely of parent material.

FSW is primarily used in aluminum and complex structure such as stocked copper, diversified intensity of fins and precision hole drilling.

Our capacity of FSW process as below: (mm)

Competitive Price: Join smaller extrusion block to larger size heat sink to reduce cost.

Limitless Size: Zero limitation in width gives high flexibility in larger project. (see capacity chart above)

Practical Process: No filler material, low energy consumption, shorter lead time.

Stable Quality: Similar characteristics and high resistance to fatigue stress as bond between two pieces is made of the original material.

Advanced Technology: Simple and automatic stirring machine eliminates set-up cost and operates in multi-directions including vertical and horizontal.

Flexibility & Functionality: Welding different alloys such as stocked copper, diversified intensity of fins and do precision hole drilling.

Other than FSW process, we provide complete variety of heat sink in different process like extrusion, skive, forge, die casting and CNC machining, as well as wide range of dimensions DC/AC fan and blower.

Regarding to any issue of thermal solution and heat dissipation, we are always ready with our passionate enthusiasm to provide you professional cooling advice. For more information of our products, please visit our website. If you have any question, please feel free to contact us.

ZAWARD CORPORATION

www.zaward.com

TEL: +886-2-2221-7098 FAX.: +886-2-2221-7200

e-mail: info@zaward.com